Manufacturers sometimes see XR (extended reality) technologies like AR (augmented reality) and VR (virtual reality) as a bit of a gimmick — a flashy toy that sounds cool but isn’t really practical or scalable. Understandably, that leaves many companies hesitant to invest in XR, fearing high costs for limited use.

But XR can be a scalable, repeatable process that offers ongoing value for manufacturing firms. XR tech can create better sales content, improve training, facilitate remote maintenance and support, and even help in product design.

In this article, we’ll look at the real-world use cases of XR in manufacturing, flag common challenges to watch out for, and walk you through how to get started.

What is extended reality?

XR (extended reality) is the umbrella term for immersive technologies that blend the digital and physical worlds to create interactive environments that can be used for entertainment, sales, design, and training.

XR tech can be broken into three categories:

1. Virtual reality (VR)

- A wholly digital immersive environment, usually viewed through a VR headset

- Often used for training simulations or manufacturing design (or video games)

2. Augmented reality (AR)

- Enhances the real world by letting you overlay digital objects (like an image, 3D model, or text) onto your physical surroundings. Think of those apps that let you see how the furniture would look in your own space.

- Usually viewed via a standard mobile device or AR glasses

3. Mixed reality (MR)

- Blends the digital and physical environments together, so you can interact with the digital elements as if they were real

- Usually accessed via an advanced XR device like the Microsoft HoloLens 2

- Often used for advanced simulations and collaboration — for example, a technician seeing a virtual machine overlay on a real machine, and manipulating the virtual controls as part of a simulation

Extended reality in manufacturing: Common use cases

So far, so sci-fi — but many of our manufacturing customers are already using XR technologies to solve complex problems, improve their training programs, and create virtual selling environments.

Here are a few of the ways that manufacturing firms can take advantage of the developments in XR tech:

1. Sales

Instead of creating a static PDF with photos of your products, with AR or VR, you can display detailed 3D models that give prospective buyers a far more comprehensive understanding of their features.

A few use cases here:

- Let your prospects customize and view virtual products, so they “feel real” and therefore more enticing to buy

- Bring static content to life, by overlaying digital elements onto physical objects like tradeshow booths or signage

- Use a mobile app that lets customers see how your products would look in their environment

- Create a virtual showroom where your customers can “walk around” your products without leaving the comfort of their own home

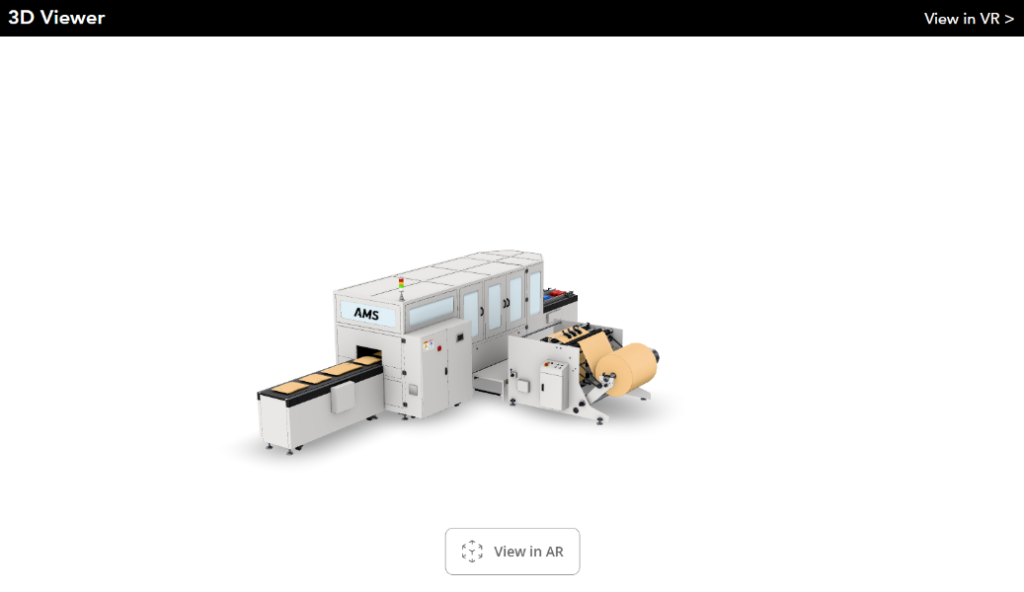

For example, our customer IPG uses XR extensively on their website to showcase their products.

Customers can wander around their virtual showroom, view their packaging machines in 3D, and zoom in on key features at their leisure. Plus, with their augmented reality features, you can visualize how the machinery would fit into your workspace.

2. Sales enablement

XR tech doesn’t just help inform and engage your customers — it can be extremely helpful for empowering your sales teams. For instance:

- Create virtual models of complex machinery or equipment, so sales reps can learn the functionality of each feature in a hands-on, interactive way without needing access to physical prototypes.

- Use AR or VR simulations to let sales teams practice challenging sales scenarios in a more realistic environment.

3. Employee training

XR tools can make a far more interactive, flexible learning experience for technical teams, too. Given that employee tenure in manufacturing is currently just 3.9 years, efficient and effective training will be a priority for many organizations in 2025 and beyond.

With XR, you can:

- Train new technicians to interact with easily damaged machinery in a virtual environment, avoiding any expensive mistakes or risk of injury

- Provide more interactive and informative product manuals, so employees can simply scan a specific part of the product to learn how to use it.

- Allow learners to choose their own adventure and explore products in their own way.

To see how VR and AR tools can help level up your manufacturing sales enablement process, set up a demo.

4. Remote learning

AR can also help create shared learning experiences for remote teams — especially helpful for training your teams on large-scale or potentially dangerous equipment.

For instance, you can give team members a QR code that they can scan, allowing them to view a virtual object in their own environment. They can then engage with the same educational content about the object, at the same time, without needing to travel.

Virtual walkthrough of a new packaging machine on a Bigtincan 3D model

5. Simplifying assembly processes

Some manufacturers, like Airbus, use AR glasses to overlay digital instructions during complex assembly processes, giving employees step-by-step guidance. Others use XR tech to allow employees to collaborate remotely on assembly tasks, for instance by allowing assembly experts to offer feedback and instructions without needing to be physically present.

6. Facilitating maintenance and repair

Overlaying instructions and diagrams onto real-world equipment can make it easier for technicians to quickly identify and fix product issues, without needing to travel to the site.

7. Supporting iterative product development

Many manufacturers are starting to include AR and VR solutions in their product development process. Instead of creating expensive physical prototypes, designers can build 3D models that allow them to quickly modify and iterate the design. For instance, McLaren uses VR to create highly realistic virtual models of their latest cars.

8. Offering better customer support

XR solutions make it easier to offer your customers remote assistance —for example, with remotely guided maintenance and repair, or interactive installation walkthroughs and product manuals.

Common challenges with using extended reality in manufacturing organizations

While there are many compelling potential use cases for XR in manufacturing, there’s still a lot of hesitation about introducing it. Here are a few common issues we see, as well as the solution we’d propose:

Problem #1: XR projects seem too hard to scale

If firms have “dabbled” with XR solutions in the past, they often perceive XR as time-intensive and expensive. Building CAD models of your products can be somewhat time-consuming, especially if you don’t have internal expertise. Too many organizations create a single XR project, use it in a single website or trade show, and decide that it was too time-consuming and costly to be worth repeating.

Solution:

The investment in XR is front-loaded. It may be time-consuming to create the initial 3D model, but those models can then be reused in multiple formats, in everything from sales collateral to training materials to customer onboarding information.

For instance, if you use Bigtincan’s AR and VR tools, you could create a model of your product and add specific touchpoints which then provide specific information about that aspect or feature. That way, you can give a guided interaction with the product.

But you can easily change and customize those touchpoints, for example by letting a customer choose what order they view them in, so they have a fully personalized interaction.

To make XR scalable, aim to develop a reusable framework for your XR projects — for instance, by standardizing 3D model creation so you can repurpose the models for multiple applications. Use an asset library to manage your models, keep them consistent, and reduce accidental duplication of effort.

Problem #2: You’re too vague about how you’ll use the XR tools

Another issue that we see in the market is when customers aren’t completely clear about why they’re trialing XR. They decide to give it a go, to see if it makes sense for their organization — but they’re vague about the initial use case.

This is a problem because the first XR project you undertake is going to be the most time-consuming and tricky. If you haven’t been very selective about the reason you’re using XR, the potential ROI of introducing the new tool, then you aren’t going to be able to make an informed decision. Too many XR newbies try to keep their options open with their first project, and end up with a solution that doesn’t really meet any one particular need.

Solution:

Be extremely specific about the intention of your initial XR project. Consider where XR tools could provide the greatest ROI. For instance, could you immediately reduce training costs if you could offer virtual training? Then, create a single model or set of models for that narrow, specific use case.

Problem #3: You’re not sure how to include extended reality in training content

Another issue we come across is that organizations are keen to level up their employee training by including virtual learning experiences, but aren’t sure exactly how. Moving from 2D to 3D content changes the learning experience pretty dramatically, and you do need to take it into account when you’re building XR learning content.

Solution:

When you’re introducing XR elements, work closely with your instructional designers to incorporate them more effectively in training materials. Because XR allows you to create a more hands-on learning experience, it can make your learning content easier to understand and retain — but only if it’s part of a well-designed learning program.

It’s time to put XR to work

XR tools aren’t a gimmick — they’re powerful technologies that can transform the way manufacturers sell, train, and operate. By investing in scalable XR solutions and focusing on high-ROI use cases, you can increase process efficiency and create engaging, impactful experiences for employees and customers alike.

Learn more about Bigtincan’s AR and VR features, or take a deeper look into the future of XR and its applications across industries with our on-demand webinar, Beyond Reality: How XR is Shaping the Future of Business.